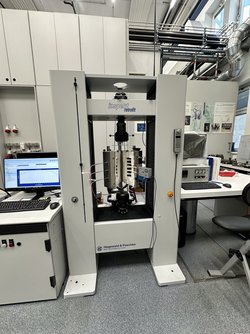

Tensile compression testing machine (UPM 250 kN)

Universal testing machine with a wide test frame for carrying out tensile, compression and bending tests up to maximum loads of 250 kN.

Technical Data:

- Technical Data:

- Manufacturer: Hegewald&Peschke (Revision 2024)

- Model: inspekt retrofit 1485 250kN

- Fmax: ±250 kN

- Working space: 1570 x 1030 mm

- Testing speed: 0.1µm bis 400 mm/min

- Macro displacement transducer: L0=10-200 mm

- Clamping device: hydraulic system

- Software: LabMaster

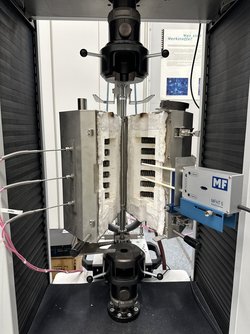

Tensile compression testing machine with high-temperature furnace (UPM 50 kN)

Universal testing machine for carrying out tensile, compression and bending tests up to maximum loads of 50 kN. Option for high-temperature tests up to 1000°C

Technical Data:

- Manufacturer: Hegewald&Peschke (Revision 2024)

- Model: inspekt retrofit AGG 50kN

- Fmax: ±50 kN

- Working space: 910 x 570 mm

- Testing speed: 0.1µm bis 500 mm/min

- Macro displacement transducer: L0=10-60 mm

- Clamping device: mechanical system

- Software: LabMaster+ SteadyRise furnace control

- Additions: high temperature furnace from 200 to 1000°C

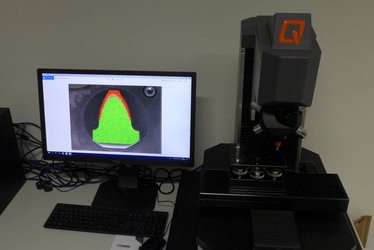

Automated Vickers hardness testing equipment

Automates hardness testing equipment for single tests, hardness line profiles (for analysing the nitriding depth and hardness penetration depth).

Technical Data:

- Manufacturer: Qness

- Type: Q60A+

- Testing method: HV (HV0,001-HV60)

Charpy-Test

The impact testing machine RKP450 is built for instrumented testing according to Charpy and IZOD, as well as for tensile impact testing. The machine has a chamber that allows the temperature control of samples from -190 °C to 700 °C. The test starts automatically after the desired temperature is reached.

Technical data:

- Designation: RKP450

- Impact energy: 300 J or 450 J / instrumented

- Testing temperature: -190°C to 700°C

Servo-hydraulic testing machine (1 and 2)

Hydraulic fatigue testing machines are used to determine S/N-curves (Woehler curves), endurance limits and to test materials in LCF-and HCF-areas. The testing can be done also in corrosive environment.

Technical Data:

- Manufacturer: Schenck

- Static Fmax: ±100 kN

- Dynamic Fmax: ±100 kN

- Testing frequency: 150 Hz

- Equipment: Corrosion testing device, furnace up to 1100°C

Rotational bending test

The machine allows estimation of rotational bending moments. Tests can be done in air and in corrosive environments.

Technical Data:

- Manufacturer: Schenk

- Dynamic moment: 0 – 1000 Ncm

- Testing frequency: 100 Hz / 200Hz

- Clamping device: mechanical

- Environment: air, corrosion test in saline solution

Vickers/Brinell hardness testing

Hardness testing and evaluation of the strength of metallic materials according to the Vickers and Brinell method. The device type M4C 025 G3M allows load up to 2,5 kN. The testing is done according to DIN EN ISO 6507 and DIN EN ISO 6506.

Technical Data:

- Manufacturer: EMCO-Test

- Type: M4C 025 G3M

- Testing method: HV (HV1-HV100)

HB (for example: 2,5/187,5/15) - Load: 2,5 kN

- Resolution: 0,1 HV respectively 0,1 HB

Rockwell hardness testing

Two devices are available for Rockwell hardness testing. The testing on the EMCO Test M4R-075 is carried out according to the Rockwell C method (HRC), using a diamond cone and a test load of 98 N (10 kp) or 1373 N (140 kp). The tests are performed in accordance with DIN EN ISO 6508.

The Mitutoyo Durotwin Rockwell hardness tester can be used not only for standard Rockwell hardness testing but also for evaluating the adhesion strength of thin hard coatings in accordance with VDI Guideline 3198. In this method, a Rockwell-C diamond is pressed into a coated substrate with sufficient hardness using a test load of 1.47 kN. The resulting coating delamination around the indentation is classified into one of the six VDI adhesion strength classes.

Technical specifications (EMCO M4R-075):

• Manufacturer: EMCO Test

• Model: M4R-075

• Test method: HRC (according to DIN EN ISO 6508)

• Load: 1-1,4 kN

• Resolution: 0.1 HRC

Technical specifications (Mitutoyo Durotwin):

• Manufacturer: Mitutoyo

• Model: Durotwin

• Rockwell-C hardness testing (Methods A, B, C, D, F, G)

• Coating adhesion evaluation according to VDI Guideline 3198

• Maximum load: up to 1.47 kN

• Resolution: 0.5 HR