Hydrogen is regarded as a key player in the future of sustainable metals production. Yet, it is also notorious for its detrimental effects on metals, namely, hydrogen embrittlement. Is hydrogen destined to remain the unwanted guest in materials science?

Not necessarily: Researchers from Montanuniversität Leoben, in a study recently published in Advanced Science, demonstrate that hydrogen can also be harnessed as a powerful tool to create otherwise unattainable microstructures.

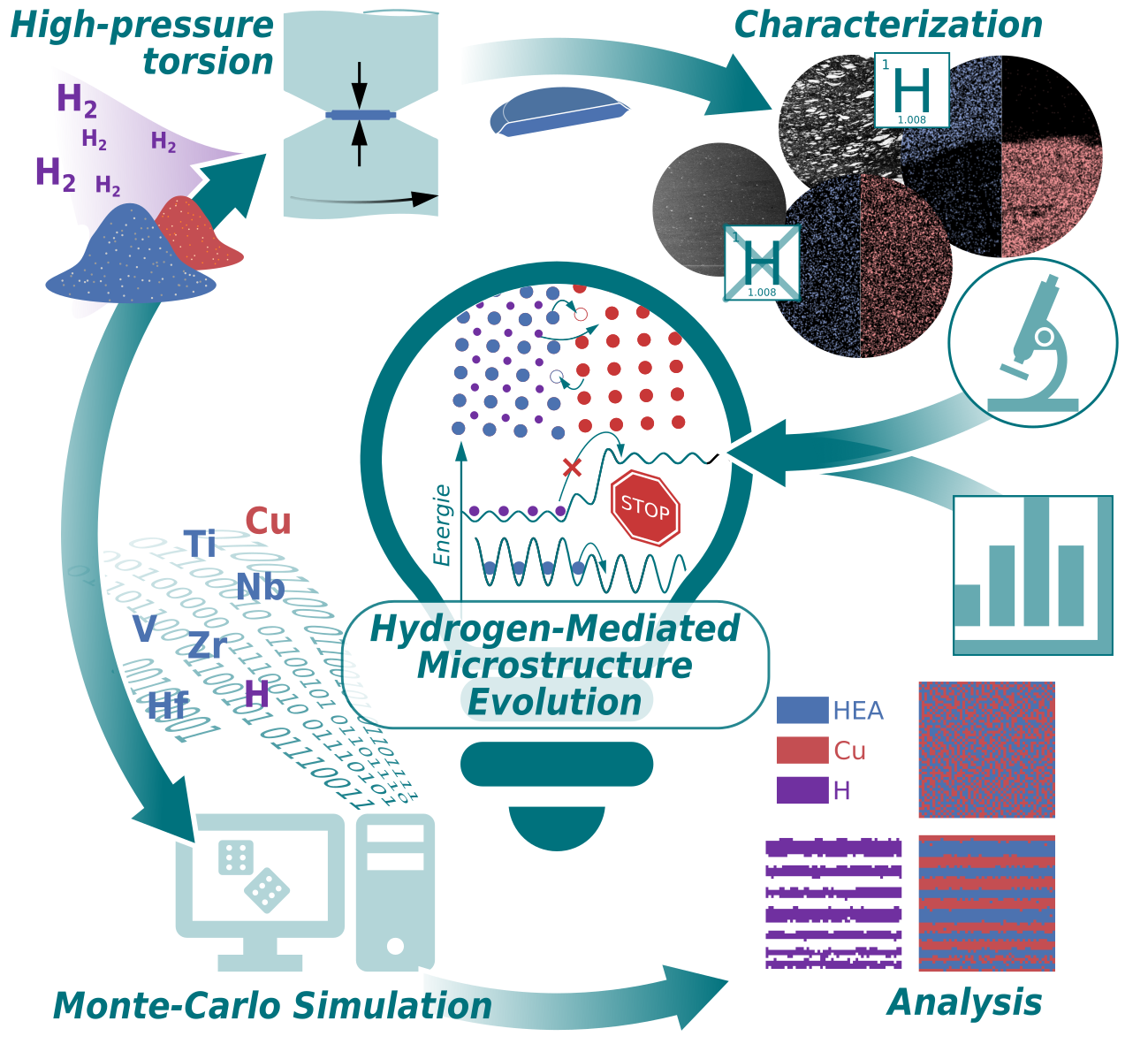

In their work, severe plastic deformation of a composite made from the equiatomic high-entropy alloy (HEA) TiVZrNbHf and copper leads to extensive mechanical alloying and, ultimately, amorphization. However, when hydrogen is introduced by replacing the HEA with its associated metal hydride, this process is suppressed, and the two-phase structure is stabilized and preserved. Monte Carlo simulations reveal the underlying cause: the markedly different hydrogen affinities of the two phases, combined with the reduced deformability of the hydride, act as a barrier to mechanical alloying.

This “hydride route” opens a new pathway for controlling microstructure evolution, even in well-studied material systems, giving materials scientists an extra dimension in material design – turning hydrogen from a problem into a design tool.

This research was carried out at the Department of Materials Science (Montanuniversität Leoben) and the Erich Schmid Institute (Austrian Academy of Sciences), in collaboration with the Chair of General and Analytical Chemistry, DESY Hamburg, and the University of Vienna. This collaborative effort underscores Montanuniversität Leoben’s commitment to advancing hydrogen-related materials research in partnership with leading national and international institutions.

advanced.onlinelibrary.wiley.com/doi/full/10.1002/advs.202507168