Design and Architectur of Functional Materials Systems

Increasing demands of industrial applications on long-lasting surface protection, enhanced mechanical, electrical and thermal properties, but also decoration or long term preservation of base materials requires development of new advanced functional coatings with unique properties. This is, however, not possible without an understanding of the complex relationships between microstructure, phase composition, stress state and mechanical and other physical properties of the coatings. The complexity of this problem thus calls for a multidisciplinary approach of materials science combining advanced experimental and modeling studies.

The attempt of the Group for Design and Architecture of Functional Materials Systems is to solve such fundamental problems related to structure-dependent functional properties of thin solid films prepared by unconventional processes in discharge plasmas, with the main focus on mechanical and thermo-mechanical properties.

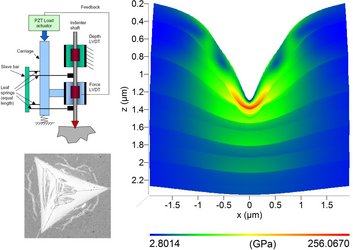

The investigations are based on structural studies of depth-profile variations in film texture, morphology, stress state and thermal properties by transmission electron microscopy, advanced X-ray diffraction, Raman and X-ray photoelectron spectroscopy, and atomic force microscopy as well as on micromechanical studies of deformation mechanisms by tension, compression and bending. In order to understand the effect of various loading conditions on the coating performance, experimental nanoindentation with Berkovich, cube corner and spherical indenters is typically combined with analytical and finite element modeling, giving an insight to the stress field developed underneath the indenting tip. The findings allow adjusting the stress state and stress gradients in single and multilayered functional nanocrystalline coatings by their controlled growth. This scientific approach is the basis for establishing a know-how base for the design of functional coating systems with improved performance.