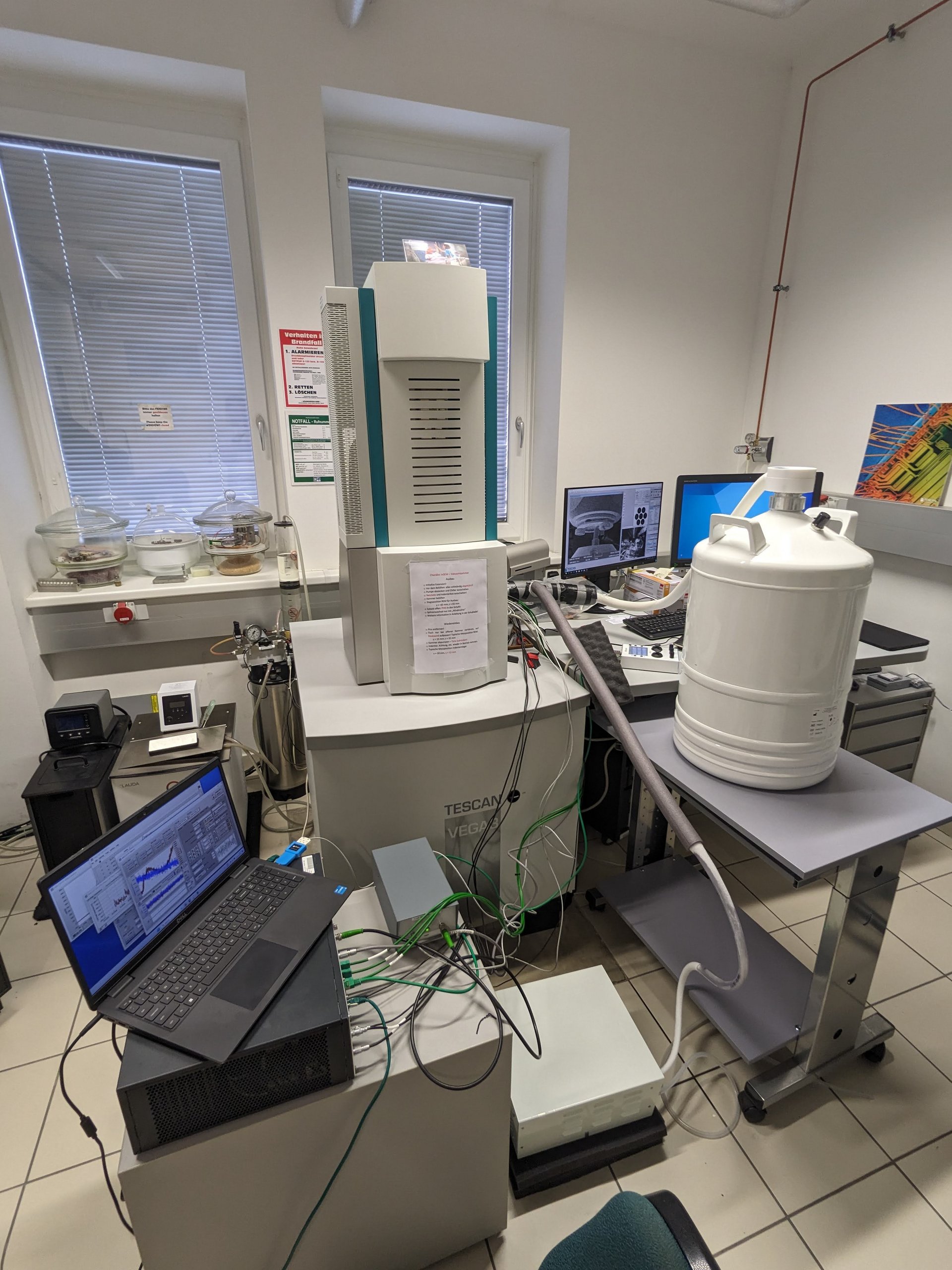

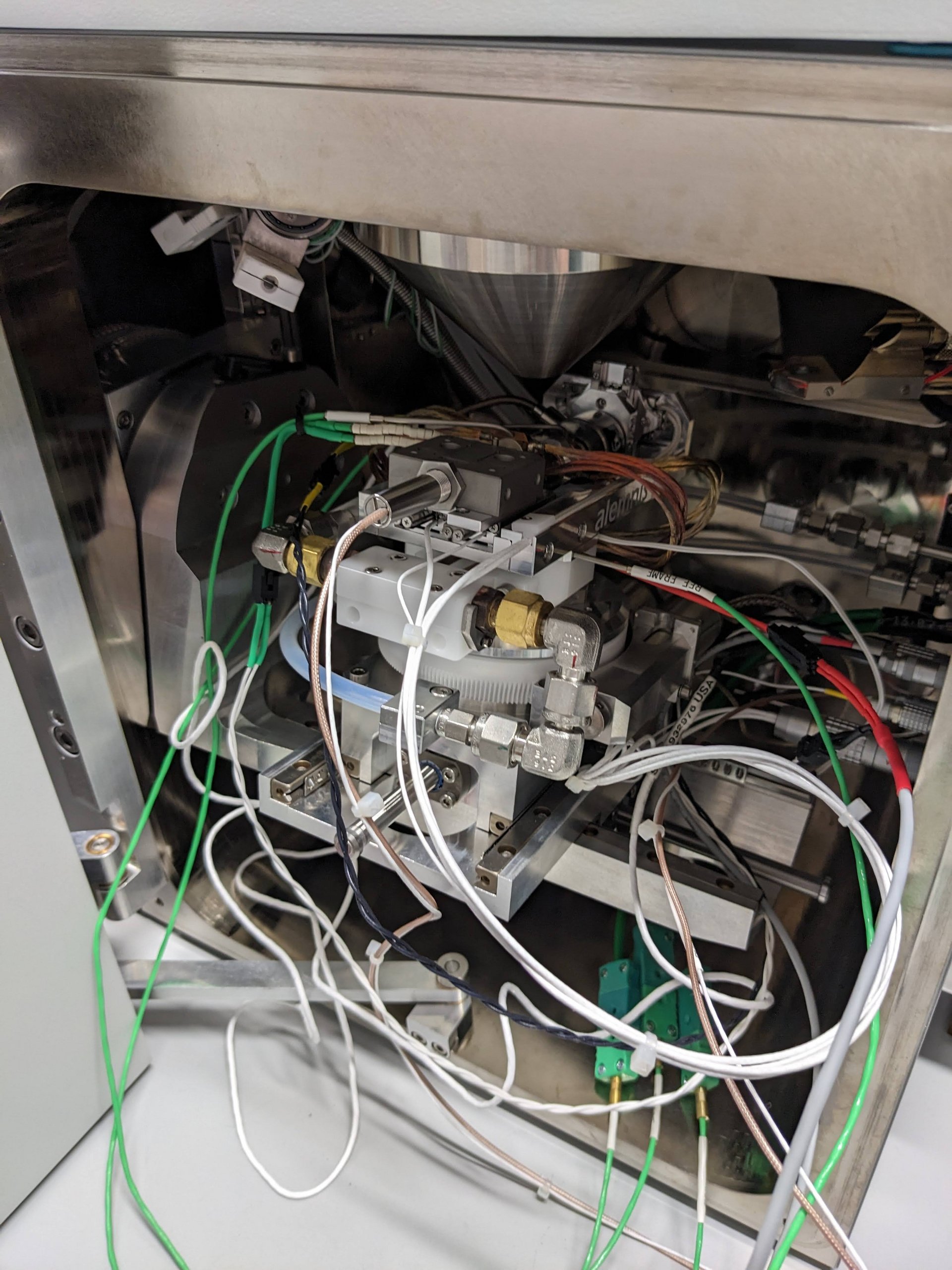

With the newly installed nanoindentation platform from Alemnis, the capabilities for micro- and nanomechanical testing available at the Department have been significantly extended. The modular design allows to use the Alemnis Standard Assembly (ASA) for in-situ and ex-situ experiments at room temperature, while the additional Low Temperature Module (LTM-CRYO) can be utilized to perform in-situ experiments at temperatures between -150 °C and 200 °C. In the ex-situ configuration, the ASA can be used as a stand-alone nanoindenter equipped with an optical microscope to navigate over the sample surface. For live observation of indentation or micromechanical experiments, the setup can be installed into the available Tescan Vega scanning electron microscope. This in-situ configuration allows to use the LTM-CRYO module, where liquid nitrogen cooling enables controlled indentation experiments at cryogenic temperatures.

In addition to its capacity for conducting tests at cryogenic temperatures, the new indentation system distinguishes itself with its intrinsic displacement control mechanism. Unlike the load-controlled indentation systems existing at the Department, this feature enables superior control, particularly during micromechanical experiments.

Future application areas of the new cryo-indentation system are the evaluation of structural and functional materials for energy technology, with a strong focus on hydrogen production, transportation, storage and utilization. The new Alemnis device expands the palette of nanoindentation systems available at the Department, now enabling measurements under an extremely wide range of harsh conditions in the temperature range between -150 and 1000 °C.