The Chair for Structural and Functional Ceramics at the University of Leoben, together with the Jožef Stefan Institute in Slovenia, published a paper in the highly respected journal "Additive Manufacturing". In the publication, "High-strength lihtography-based additive manufacturing of ceramic components with rapid sintering," a new sintering method for complex 3D-printed ceramic components was investigated to obtain dense ceramics with targeted structural and mechanical properties within a few minutes.

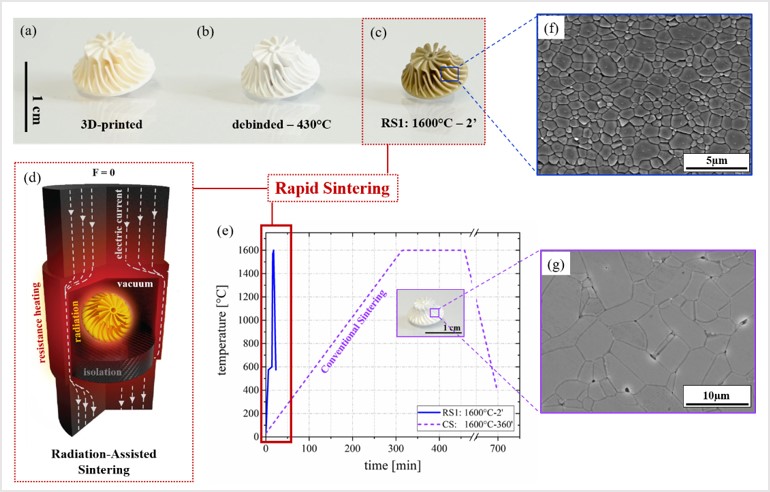

Until now, the densification of additively manufactured ceramics has mainly taken place in conventional sintering furnaces with standard conditions. The result is usually dense ceramics but often very coarse-grained microstructures. In the published work, the radiation-assisted sintering (RAS) method was used to rapidly sinter 3D printed alumina ceramics with heating rates of ~300-450°C/min. The "lithography-based ceramic manucaturing" (LCM) technology available at the Chair for Structural and Functional Ceramics was used to produce the green bodies.

It was shown that with the applied "radiation-assisted sintering" (RAS) stereolithographic additively manufactured alumina ceramics can be successfully densified in a few minutes compared to several hours. For RAS, the graphite crucible of a "spark plasma sintering" (SPS) system was modified to allow the densification of complex geometries (e.g. turbocharger engine rotor) without applying direct pressure or electric current to the component.

With the sintering process, fine-grained microstructures with grain sizes smaller than 1µm and relative densities of about 99% could be achieved with a much lower energy input of 1MJ compared to 25MJ for conventional sintering. The mechanical strength of the RAS sintered alumina samples was ~800MPa, comparatively high to standard sintering conditions (~600MPa).

The results show that RAS would be a new way to optimize the microstructural properties of additively manufactured ceramics, improving mechanical as well as functional properties. In the future, the sintering process could also be applied to biomedical, magnetic, optical, catalytic or electroceramics.